Hot air balloon

Did you know...

SOS believes education gives a better chance in life to children in the developing world too. Visit the SOS Children website at http://www.soschildren.org/

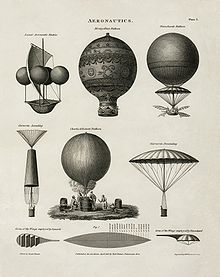

The hot air balloon is the oldest successful human-carrying flight technology. It is part of a class of aircraft known as balloon aircraft. On November 21, 1783, in Annonay, France, the first untethered manned flight was performed by Jean-François Pilâtre de Rozier and François Laurent d'Arlandes in a hot air balloon created on December 14, 1782 by the Montgolfier brothers. Hot air balloons that can be propelled through the air rather than just being pushed along by the wind are known as airships or, more specifically, thermal airships.

A hot air balloon consists of a bag called the envelope that is capable of containing heated air. Suspended beneath is a gondola or wicker basket (in some long-distance or high-altitude balloons, a capsule), which carries passengers and (usually) a source of heat, in most cases an open flame. The heated air inside the envelope makes it buoyant since it has a lower density than the relatively cold air outside the envelope. As with all aircraft, hot air balloons cannot fly beyond the atmosphere. Unlike gas balloons, the envelope does not have to be sealed at the bottom since the air near the bottom of the envelope is at the same pressure as the air surrounding. For modern sport balloons the envelope is generally made from nylon fabric and the inlet of the balloon (closest to the burner flame) is made from fire resistant material such as Nomex. Beginning during the mid-1970s, balloon envelopes have been made in all kinds of shapes, such as rocket ships and the shapes of various commercial products, though the traditional shape remains popular for most non-commercial, and many commercial, applications.

History

Premodern and unmanned balloons

Early unmanned hot air balloons were used in China. Zhuge Liang of the Shu Han kingdom, during the Three Kingdoms era (220–280 AD) used airborne lanterns for military signaling. These lanterns are known as Kongming lanterns (孔明灯). There is also some speculation, from a demonstration directed by British modern hot air balloonist Julian Nott during the late 1970s and again in 2003, that hot air balloons could have been used by people of the Nazca culture of Peru some 1500 to 2000 years ago, as an aid for designing the famous Nazca ground figures and lines. The first documented balloon flight in Europe was demonstrated by Bartolomeu de Gusmão. On August 8, 1709, in Lisbon, he managed to lift a balloon full of hot air about 4.5 meters in front of King John V and the Portuguese court.

First manned flight

The brothers Joseph-Michel and Jacques-Etienne Montgolfier developed a hot air balloon in Annonay, Ardeche, France, and demonstrated it publicly on June 4, 1783 with an unmanned flight lasting 10 minutes. After experimenting with unmanned balloons and flights with animals, the first balloon flight with humans aboard—a tethered flight—performed on or around October 15, 1783 by Etienne Montgolfier who made at least one tethered flight from the yard of the Reveillon workshop in the Faubourg Saint-Antoine. Later that same day, Pilatre de Rozier became the second human to ascend into the air, to an altitude of 80 ft (24 m) which was the length of the tether. The first free flight with human passengers occurred a few weeks later, on November 21, 1783. King Louis XVI had originally decreed that condemned criminals would be the first pilots, but de Rozier, along with Marquis François d'Arlandes, petitioned successfully for the honour. The first military use of a hot air balloon happened during the battle of Fleurus in Europe (1794), with the French using the balloon l'Entreprenant as an observation post.

Today

Modern hot air balloons, with an onboard heat source, were developed by Ed Yost, beginning during the 1950s; his work resulted in his first successful flight, on October 22, 1960. The first modern hot air balloon to be made in the United Kingdom (UK) was the Bristol Belle during 1967. Presently, hot air balloons are used primarily for recreation.

Hot air balloons are able to fly to extremely high altitudes. On November 26, 2005, Vijaypat Singhania set the world altitude record for highest hot air balloon flight, reaching 21,027 m (68,986 ft). He took off from downtown Mumbai, India, and landed 240 km (150 mi) south in Panchale. The previous record of 19,811 m (64,997 ft) had been set by Per Lindstrand on June 6, 1988 in Plano, Texas. As with all unpressurized aircraft, oxygen is needed for all aboard any flight that exceeds an altitude of about 15,000 ft (4,600 m).

On January 15, 1991, the Virgin Pacific Flyer balloon completed the longest flight in a hot air balloon when Per Lindstrand (born in Sweden, but resident in the UK) and Richard Branson of the UK flew 7,671.91 km (4,767.10 mi) from Japan to Northern Canada. With a volume of 74 thousand cubic meters (2.6 million cubic feet), the balloon envelope was the largest ever built for a hot air craft. Designed to fly in the trans-oceanic jet streams, the Pacific Flyer recorded the fastest ground speed for a manned balloon at 245 mph (394 km/h). The longest duration record was set by Swiss psychiatrist Bertrand Piccard, Auguste Piccard's grandson, and Briton Brian Jones, flying in the Breitling Orbiter 3. It was the first nonstop trip around the world by balloon. The balloon left Château-d'Oex, Switzerland, on March 1, 1999, and landed at 1:02 a.m. on March 21 in the Egyptian desert 300 miles (480 km) south of Cairo. The two men exceeded distance, endurance, and time records, traveling 19 days, 21 hours, and 55 minutes. Steve Fossett exceeded the record for briefest time traveling around the world on 3 July 2002. The new record is 320 h 33 min.

Construction

A hot air balloon for manned flight uses a single-layered, fabric gas bag (lifting "envelope"), with an opening at the bottom called the mouth or throat. Attached to the envelope is a basket, or gondola, for carrying the passengers. Mounted above the basket and centered in the mouth is the "burner", which injects a flame into the envelope, heating the air within. The heater or burner is fueled by propane, a liquefied gas stored in pressure vessels, similar to high pressure forklift cylinders.

Envelope

Modern hot air balloons are usually made of light-weight and strong synthetic fabrics such as ripstop nylon or dacron (a polyester).

During the manufacturing process, the material is cut into panels and sewn together, along with structural load tapes that carry the weight of the gondola or basket. The individual sections, which extend from the throat to the crown (top) of the envelope, are known as gores or gore sections. Envelopes can have as few as 4 gores or as many as 24 or more.

Envelopes often have a crown ring at their very top. This is a hoop of smooth metal, usually aluminium, and approximately 1 ft (0.30 m) in diameter. Vertical load tapes from the envelope are attached to the crown ring.

Seams

The most common technique for sewing panels together is called the French felled, French fell, or double lap seam. The two pieces of fabric are folded over on each other at their common edge, possibly with a load tape as well, and sewn together with two rows of parallel stitching. Other methods include a flat lap seam, in which the two pieces of fabric are held together simply with two rows of parallel stitching, and a zigzag, where parallel zigzag stitching holds a double lap of fabric.

Coatings

The fabric (or at least part of it, the top 1/3 for example) may be coated with a sealer, such as silicone or polyurethane, to make it impermeable to air. It is often the degradation of this coating and the corresponding loss of impermeability that ends the effective life of an envelope, not weakening of the fabric itself. Heat, moisture, and mechanical wear-and-tear during set up and pack up are the primary causes of degradation. Once an envelope becomes too porous to fly, it may be retired and discarded or perhaps used as a 'rag bag': cold inflated and opened for children to run through. Products for recoating the fabric are becoming available commercially.

Sizes and capacity

A range of envelope sizes is available. The smallest, one-person, basket-less balloons (called " Hoppers" or "Cloudhoppers") have as little as 21,000 ft³ (600 m³) of envelope volume; for a perfect sphere the radius would be around 5 m (16 ft). At the other end of the scale, balloons used by commercial sightseeing operations may be able to carry well over two dozen people, with envelope volumes of up to 600,000 cu ft (17,000 m3). The most-used size is about 100,000 cu ft (2,800 m3), and can carry 3 to 5 people.

Vents

The top of the balloon usually has a vent of some sort. This enables the pilot to release hot air to slow an ascent, start a descent, or increase the rate of descent, usually for landing. Some hot air balloons have turning vents, which are side vents that, when opened, cause the balloon to rotate. Such vents are particularly useful for balloons with rectangular baskets, to facilitate aligning the wider side of the basket for landing.

The most common type of top vent is a disk-shaped flap of fabric called a parachute vent, invented by Tracy Barnes. The fabric is connected around its edge to a set of "vent lines" that converge in the centre. (The arrangement of fabric and lines roughly resembles a parachute—thus the name.) These "vent lines" are themselves connected to a control line that runs to the basket. A parachute vent is opened by pulling on the control line. Once the control line is released, the pressure of the remaining hot air pushes the vent fabric back into place. A parachute vent can be opened briefly while in flight to initiate a rapid descent. (Slower descents are initiated by allowing the air in the balloon to cool naturally.) The vent is pulled open completely to collapse the balloon after landing.

An older, and presently less commonly used, style of top vent is called a " Velcro-style" vent. This too is a disk of fabric at the top of the balloon. However, rather than having a set of "vent lines" that can repeatedly open and close the vent, the vent is secured by "hook and loop" fasteners (such as Velcro) and is only opened at the end of the flight. Balloons equipped with a Velcro-style vent typically have a second "maneuvering vent" built into the side (as opposed to the top) of the balloon. Another common type of top design is the "Smart Vent," which, rather than lowering a fabric disc into the envelope as in the "parachute" type, gathers the fabric together in the centre of the opening. This system can theoretically be used for in-flight maneuvering, but is more commonly used only as a rapid-deflation device for use after landing, of particular value in high winds. Other designs, such as the "pop top" and "MultiVent" systems, have also attempted to address the need for rapid deflation on landing, but the parachute top remains popular as an all-around maneuvering and deflation system.

Shape

Besides special shapes, possibly for marketing purposes, there are several variations on the traditional "inverted tear drop" shape. The simplest, often used by home builders, is a hemisphere on top of a truncated cone. More-sophisticated designs attempt to minimize the circumferential stress on the fabric, with different degrees of success depending on whether they take fabric weight and varying air density into account. This shape may be referred to as "natural". Finally, some specialized balloons are designed to minimize aerodynamic drag (in the vertical direction) to improve flight performance in competitions.

Basket

Baskets are commonly made of woven wicker or rattan. These materials have proven to be sufficiently light, strong, and durable for balloon flight. Such baskets are usually rectangular or triangular in shape. They vary in size from just big enough for two people to large enough to carry thirty. Larger baskets often have internal partitions for structural bracing and to compartmentalize the passengers. Small holes may be woven into the side of the basket to act as foot holds for passengers climbing in or out.

Baskets may also be made of aluminium, especially a collapsible aluminium frame with a fabric skin, to reduce weight or increase portability. These may be used by pilots without a ground crew or who are attempting to set altitude, duration, or distance records. Other specialty baskets include the fully enclosed gondolas used for around-the-world attempts, and baskets that consist of little more than a seat for the pilot and perhaps one passenger.

Burner

The burner unit gasifies liquid propane, mixes it with air, ignites the mixture, and directs the flame and exhaust into the mouth of the envelope. Burners vary in power output; each will generally produce 2 to 3 MW of heat (7 to 10 million BTUs per hour), with double, triple, or quadruple burner configurations installed where more power is needed. The pilot actuates a burner by opening a propane valve, known as a blast valve. The valve may be spring-loaded so that it closes automatically, or it may stay open until closed by the pilot. The burner has a pilot light to ignite the propane and air mixture. The pilot light may be lit by the pilot with an external device, such as a flint striker or a lighter, or with a built-in piezo electric spark.

Where more than one burner is present, the pilot can use one or more at a time depending on the desired heat output. Each burner is characterized by a metal coil of propane tubing the flame shoots through to preheat the incoming liquid propane. The burner unit may be suspended from the mouth of the envelope, or supported rigidly over the basket. The burner unit may be mounted on a gimbal to enable the pilot to aim the flame and avoid overheating the envelope fabric. A burner may have a secondary propane valve that releases propane more slowly and thereby generates a different sound. This is called a whisper burner and is used for flight over livestock to lessen the chance of spooking them. It also generates a more yellow flame and is used for night glows because it lights up the inside of the envelope better than the primary valve.

Fuel tanks

Propane fuel tanks are usually cylindrical pressure vessels made from aluminium, stainless steel, or titanium with a valve at one end to feed the burner and to refuel. They may have a fuel gauge and a pressure gauge. Common tank sizes are 10 (38), 15 (57), and 20 (76) US gallons ( liters). They may be intended for upright or horizontal use, and may be mounted inside or outside the basket.

The pressure necessary to force the fuel through the line to the burner may be supplied by the vapor pressure of the propane itself, if warm enough, or by the introduction of an inert gas such as nitrogen. Tanks may be preheated with electrical heat tapes to produce sufficient vapor pressure for cold weather flying. Warmed tanks will usually also be wrapped in an insulating blanket to preserve heat during the setup and flight.

Instrumentation

A balloon may be outfitted with a variety of instruments to aid the pilot. These commonly include an altimeter, a rate of climb (vertical speed) indicator known as a variometer, envelope (air) temperature, and ambient (air) temperature. A GPS receiver can be useful to indicate ground speed (traditional aircraft air speed indicators would be useless) and direction.

Combined mass

The combined mass of an average system can be calculated as follows:

-

component pounds kilograms 100,000 cu ft (2,800 m3) envelope 250 113.4 5-passenger basket 140 63.5 double burner 50 22.7 3 20-gallon (75.7-liter) fuel tanks full of propane 3 × 135 = 405 183.7 5 passengers 5 × 150 = 750 340.2 sub total 1595 723.5 100,000 cu ft (2,800 m3) of heated air 5922 2686.2 total (3.76 tons) 7517 3409.7

using a density of 0.9486 kg/m³ for dry air heated to 210 °F (99 °C).

Theory of operation

Generating lift

Increasing the air temperature inside the envelope makes it lighter than the surrounding (ambient) air. The balloon floats because of the buoyant force exerted on it. This force is the same force that acts on objects when they are in water and is described by Archimedes' principle. The amount of lift (or buoyancy) provided by a hot air balloon depends primarily upon the difference between the temperature of the air inside the envelope and the temperature of the air outside the envelope. For most envelopes made of nylon fabric, the maximum internal temperature is limited to approximately 120 °C (250 °F).

It should be noted that the melting point of nylon is significantly greater than this maximum operating temperature — about 230 °C (450 °F). However the lower temperatures are generally used because the greater the temperature, the more quickly the strength of the nylon fabric degrades over time. With a maximum operating temperature of 120 °C (250 °F), balloon envelopes can generally be flown for between 400 and 500 hours before the fabric needs to be replaced. Many balloon pilots operate their envelopes at temperatures significantly less than the maximum to extend envelope fabric life.

The lift generated by 100,000 ft³ (2831.7 m³) of dry air heated to various temperatures may be calculated as follows:

-

air temperature air density air mass lift generated 68 °F, 20 °C 1.2041 kg/m³ 7517 lb, 3409.7 kg 0 lb, 0 kg 210 °F, 99 °C 0.9486 kg/m³ 5922 lb, 2686.2 kg 1595 lb, 723.5 kg 250 °F, 120 °C 0.8978 kg/m³ 5606 lb, 2542.4 kg 1912 lb, 867.3 kg

The density of air at 20 °C, 68 °F is about 1.2 kg/m³. The total lift for a balloon of 100,000 ft³ heated to (99 °C, 210 °F) would be 1595 lb, 723.5 kg. This is just enough to generate neutral buoyancy for the total system mass (not including the heated air trapped in the envelope, of course) stated in the previous section. Liftoff would require a slightly greater temperature, depending on the desired rate of climb. In reality, the air contained in the envelope is not all the same temperature, as the accompanying thermal image shows, and so these calculations are based on averages.

For typical atmospheric conditions (20 °C, 68 °F), a hot air balloon heated to (99 °C, 210 °F) requires about 3.91 m³ of envelope volume to lift 1 kilogram (62.5 ft³/lb). The precise amount of lift provided depends not only upon the internal temperature mentioned above, but the external temperature, altitude above sea level, and humidity of the air surrounding. On a warm day, a balloon cannot lift as much as on a cool day, because the temperature required for launch will exceed the maximum sustainable for nylon envelope fabric. Also, in the lower atmosphere, the lift provided by a hot air balloon decreases about 3% for each 1,000 meters (1% per 1,000 ft) of altitude gained.

Montgolfier

Standard hot air balloons are known as Montgolfier balloons and rely solely on the buoyancy of hot air provided by the burner and contained by the envelope. This style of balloon was developed by the Montgolfier brothers, and had its first public demonstration on 4 June 1783 with an unmanned flight lasting 10 minutes, followed later that year with manned flights.

Hybrid

The 1785 Rozière balloon, a type of hybrid balloon, named after its creator, Jean-François Pilâtre de Rozier, has a separate cell for a lighter than air gas (typically helium,) as well as a cone below for hot air (as is used in a hot air balloon) to heat the helium at night. Hydrogen gas was used in the very early stages of development but was quickly abandoned due to the obvious danger of introducing an open flame near the gas. All modern Roziere balloons now use helium as a lifting gas.

Solar

Solar balloons are hot air balloons that use just solar energy captured by a dark envelope to heat the air inside.

Safety equipment

To help ensure the safety of pilot and passengers, a hot air balloon may carry several pieces of safety equipment.

In the basket

To relight the burner if the pilot light goes out and the optional piezo ignition fails, the pilot should have ready access to a flint spark lighter. Many systems, especially those that carry passengers, have completely redundant fuel and burner systems: two fuel tanks, connected to two separate hoses, which feed two distinct burners. This enables a safe landing in the case of a clog somewhere in one system or if a system must be disabled because of a fuel leak.

A fire extinguisher suitable for extinguishing propane fires is a useful piece of safety equipment in a balloon. Most balloons carry a 1 kg AB:E type fire extinguisher.

A handling or drop line is mandatory safety equipment in many countries. It is a rope or webbing of 20 – 30 meters in length attached to the balloon basket with a quick release connection at one end. In very calm wind conditions the balloon pilot can throw the handling line from the balloon so that the ground crew can guide the balloon safely away from obstructions on the ground.

On the occupants

At a minimum the pilot should wear flame resistant gloves. These can be made of leather or some more sophisticated material, such as nomex. These will enable the pilot to shut off a gas valve in the case of a leak even if there is a flame present. Quick action on the pilot's part to stop the flow of gas can turn a potential disaster into an inconvenience. In addition, the pilot should wear clothing made of natural fibers. These will singe and not burn readily if brought into contact with an open flame. Many synthetic fibers, unless especially formulated for use near flame or high temperatures like nomex, will melt onto the wearer and can cause severe burning. Finally, some balloon systems, especially those that hang the burner from the envelope instead of supporting it rigidly from the basket, require the use of helmets by the pilot and passengers.

On the ground crew

The ground crew should wear gloves on their hands whenever the possibility of handling ropes or lines exists. The mass and exposed surface to air movement of a medium sized balloon is sufficient to cause rope friction burns to the hands of anyone trying to stop or prevent movement. The ground crew should also wear sturdy shoes and at least long pants in case of the need to access a landing or landed balloon in rough or overgrown terrain.

Maintenance and repair

As with aircraft, hot air balloons require regular maintenance to remain airworthy. As aircraft made of fabric and that lack direct horizontal control, hot air balloons may occasionally require repairs to rips or snags. While some operations, such as cleaning and drying, may be performed by the owner or pilot, other operations, such as sewing, must be performed by a qualified repair technician and recorded in the balloon's maintenance log book.

Maintenance

To ensure long life and safe operation, the envelope should be kept clean and dry. This prevents mold and mildew from forming on the fabric and abrasion from occurring during packing, transport, and unpacking due to contact with foreign particles. In the event of a landing in a wet (because of precipitation or early morning or late evening dew) or muddy location (farmer's field), the envelope should be cleaned and laid out or hung to dry.

The burner and fuel system must also be kept clean to ensure safe operation on demand. Damaged fuel hoses need to be replaced. Stuck or leaky valves must be repaired or replaced. The wicker basket may require occasional refinishing or repair. The skids on its bottom may require occasional replacement.

Balloons in most parts of the world are maintained in accordance with a fixed manufacturer's maintenance schedule that includes regular (100 flight hours or 12 month) inspections, in addition to maintenance work to correct any damage. In Australia, balloons used for carrying commercial passengers must be inspected and maintained by approved workshops.

Repair

In the case of a snag, burn, or rip in the envelope fabric, a patch may be applied or the affected panel completely replaced. Patches may be held in place with glue, tape, stitching, or a combination of these techniques. Replacing an entire panel requires the stitching around the old panel to be removed, and a new panel to be sewn in with the appropriate technique, thread, and stitch pattern.

Licensing

Depending on the size of the balloon, location, and intended use, hot air balloons and their pilots need to comply with a variety of regulations.

Balloons

As with other aircraft in the USA, balloons must be registered (have an N-number), have an airworthiness certificate, and pass annual inspections. Balloons below a certain size (empty weight of less than 155 pounds or 70 kg including envelope, basket, burners and empty fuel tanks) can be used as an ultralight aircraft.

Pilots

In the United States of America

In the United States, a pilot of a hot air balloon must have a pilot certificate from the Federal Aviation Administration (FAA) and it must carry the rating of "Lighter-than-air free balloon", and unless the pilot is also qualified to fly gas balloons, will also carry this limitation: "Limited to hot air balloons with airborne heater". A pilot does not need a license to fly an ultralight aircraft, but training is highly advised, and some hot air balloons meet the criteria.

To carry paying passengers for hire (and attend some balloon festivals), a pilot must have a commercial pilot certificate. Commercial hot air balloon pilots may also act as hot air balloon flight instructors. While most balloon pilots fly for the pure joy of floating through the air, many are able to make a living as a professional balloon pilot. Some professional pilots fly commercial passenger sightseeing flights, while others fly corporate advertising balloons.

In the UK

In the UK, the person in command must hold a valid Private Pilot's Licence issued by the Civil Aviation Authority specifically for ballooning; this is known as the PPL(B). There are two types of commercial balloon licences: CPL(B) Restricted and CPL(B) (Full). The CPL(B) Restricted is required if the pilot is undertaking work for a sponsor or being paid by an external agent to operate a balloon. The pilot can fly a sponsored balloon with everything paid for with a PPL unless asked to attend any event. Then a CPL(B) Restricted is required. The CPL(B) is required if the pilot is flying passengers for money. The balloon then needs a transport category C of A (certificate of air worthiness). If the pilot is only flying sponsor's guests, and not charging money for flying other passengers, then the pilot is exempted from holding an AOC (air operator's certificate) though a copy of it is required. For passenger flying the balloon also requires a maintenance log.

In Australia

In Australia, a commercial operation must operate with a nominated Chief Pilot and under an Air Operators Certificate from the Australian Civil Aviation and Safety Authority (CASA). Pilots must have different degrees of experience before they are allowed to progress to larger balloons. Hot air balloons must be registered aircraft with the CASA and are subject to regular airworthiness checks by authorised personnel.

Accidents and incidents

- 1989 Alice Springs hot air balloon crash: On 13 August 1989, two hot air balloons collided at Alice Springs, Northern Territory, Australia, killing all 13 people on board.

- 2011 Somerset hot air balloon crash: On 1 January 2011, a hot air balloon attempting a high altitude flight crashed at Pratten's Bowls Club in Westfield, Somerset, near Bath, England, killing all 2 people on board.

- 2012 Carterton hot air balloon crash: On 7 January 2012, a hot air balloon collided with a power line, caught fire and crashed at Carterton, North Island, New Zealand, killing all 11 people on board.

- 2012 Ljubljana Marshes hot air balloon crash: On 23 August 2012, a storm blew a hot air balloon to the ground, causing it to catch fire on impact near Ljubljana, Slovenia. The crash killed 6 of the 32 people on board, and injured the other 26.

- 2013 Luxor hot air balloon crash: On 26 February 2013, a hot air balloon carrying foreign tourists ignited and crashed near the ancient city of Luxor, Egypt, killing 19 of the 21 people on board, making it the deadliest balloon accident in history.

Manufacturers

The largest manufacturer of hot air balloons in the world is Cameron Balloons company of Bristol, England, which also owns Lindstrand Balloons of Oswestry, England. Cameron Balloons, Lindstrand Balloons and another English balloon manufacturing company, Thunder and Colt (since acquired by Cameron), have been innovators and developers of special shaped balloons. These hot air balloons use the same principle of lift as conventional inverted teardrop shaped balloons but often sections of the special balloon envelope shape do not contribute to the balloon's ability to stay aloft.

The second largest manufacturer of hot air balloons in the world is Ultramagic company, based in Spain, which produces from 80 to 120 balloons per year. Ultramagic can produce very large balloons, such as the N-500 that accommodates as many as 27 persons in the basket, and has also produced many balloons with special shapes, as well as cold-air inflatables.

In the USA Aerostar International, Inc. of Sioux Falls, South Dakota was North America's largest balloon manufacturer and a close second in world manufacturing before ceasing to build balloons in January 2007. Firefly Balloons, formerly The Balloon Works, is a manufacturer of hot-air balloons in Statesville, North Carolina. Another manufacturer is Head Balloons, Inc. of Helen, Georgia.

The major manufacturers in Canada are Sundance Balloons and Fantasy Sky Promotions. Other manufacturers include Kavanagh Balloons of Australia, Schroeder Fire Balloons of Germany, and Kubicek Balloons of the Czech Republic.