Boeing 787 Dreamliner

Did you know...

This wikipedia selection has been chosen by volunteers helping SOS Children from Wikipedia for this Wikipedia Selection for schools. Sponsoring children helps children in the developing world to learn too.

| Boeing 787 Dreamliner | |

|---|---|

| The first All Nippon Airways Boeing 787 | |

| Role | Wide-body jet airliner |

| National origin | United States |

| Manufacturer | Boeing Commercial Airplanes |

| First flight | December 15, 2009 |

| Introduction | October 26, 2011, with All Nippon Airways |

| Status | Certificated, currently grounded worldwide |

| Primary users | All Nippon Airways Japan Airlines United Airlines Air India |

| Produced | 2007–present |

| Number built | 49 (January 2013) |

| Program cost | US$32 billion (Boeing's expenditure as of 2011) |

| Unit cost | 787-8: US$206.8 million (2012) 787-9: US$243.6 million (2012) |

The Boeing 787 Dreamliner or simply Boeing 787 is a long-range, mid-size wide-body, twin-engine jet airliner developed by Boeing Commercial Airplanes. Its variants seat 210 to 290 passengers. Boeing states that it is the company's most fuel-efficient airliner and the world's first major airliner to use composite materials as the primary material in the construction of its airframe. The 787 has been designed to be 20% more fuel efficient than the 767 it is to replace. The Dreamliner's distinguishing features include mostly electrical flight systems, a four-panel windshield, noise-reducing chevrons on its engine nacelles, and a smoother nose contour. It shares a common type rating with the larger 777 twinjet, allowing qualified pilots to operate both models, due to related design features.

The aircraft's initial designation was 7E7, prior to its renaming in January 2005. The first 787 was unveiled in a roll-out ceremony on July 8, 2007, at Boeing's Everett assembly factory, by which time it had reached 677 orders; this is more orders from launch to roll-out than any previous wide-body airliner. By November 2012, the 787 program had logged 844 orders from 57 customers, with International Lease Finance Corporation (ILFC) having the largest number on order.

The 787 development and production has involved a large-scale collaboration with numerous suppliers around the globe. Final assembly is at the Boeing Everett Factory in Everett, Washington. Assembly is also taking place at a new factory in North Charleston, South Carolina. Both sites will deliver 787s to airline customers. Originally planned to enter service in May 2008, the project has suffered from multiple delays. The airliner's maiden flight took place on December 15, 2009, and completed flight testing in mid-2011. Final Federal Aviation Administration (FAA) and European Aviation Safety Agency (EASA) type certification was received in late August 2011 and the first model was delivered in late September 2011. It entered commercial service on October 26, 2011.

The aircraft has suffered from early in-service problems, notably fires on board related with its lithium-ion batteries. These systems are being reviewed by both the FAA and the Japanese aviation agency. On January 16, 2013, the FAA issued an emergency airworthiness directive that grounds all 787s in the U.S. The EASA, Japanese Transport Ministry, India's Directorate General of Civil Aviation (DGCA), and Chile's Dirección General de Aeronautica Civil (DGAC) followed suit and grounded the Dreamliners in their respective jurisdictions.

Development

Background

During the late 1990s, Boeing began considering replacement aircraft programs as sales for the 767 and Boeing 747-400 slowed. The company proposed two new aircraft, the 747X, which would have lengthened the 747-400 and improved efficiency, and the Sonic Cruiser, which would have achieved 15% higher speeds (approximately Mach 0.98) while burning fuel at the same rate as the existing 767. Market interest for the 747X was tepid, but the Sonic Cruiser had brighter prospects. Several major airlines in the United States, including Continental Airlines, initially showed enthusiasm for the Sonic Cruiser concept, although they also expressed concerns about the operating cost.

The global airline market was disrupted by the September 11, 2001 attacks and increased petroleum prices, making airlines more interested in efficiency than speed. The worst-affected airlines, those in the United States, had been considered the most likely customers of the Sonic Cruiser, and thus Boeing officially cancelled the Sonic Cruiser on December 20, 2002. Changing course, the company announced an alternative product using Sonic Cruiser technology in a more conventional configuration, the 7E7, on January 29, 2003. The emphasis on a smaller midsize twinjet rather than a large 747-size aircraft represented a shift from hub-and-spoke theory towards the point-to-point theory, in response to analysis of focus groups.

The replacement for the Sonic Cruiser project was dubbed the "7E7" (with a development code name of "Y2"). Technology from the Sonic Cruiser and 7E7 was to be used as part of Boeing's project to replace its entire airliner product line, an endeavor called the Yellowstone Project (of which the 7E7 became the first stage). Early concept images of the 7E7 included rakish cockpit windows, a dropped nose and a distinctive "shark-fin" tail. The "E" was said to stand for various things, such as "efficiency" or "environmentally friendly"; however, in the end, Boeing said that it merely stood for "Eight". In July 2003, a public naming competition was held for the 7E7, for which out of 500,000 votes cast online the winning title was Dreamliner. Other names in the pool included eLiner, Global Cruiser and Stratoclimber.

On April 26, 2004, Japanese airline All Nippon Airways became the launch customer for the Dreamliner, by announcing a firm order for 50 aircraft with deliveries to begin in late 2008. All Nippon Airways' order was initially specified as 30 787-3, 290–330 seat, one-class domestic aircraft, and 20 787-8, long-haul, 210–250 seat, two-class aircraft for regional international routes such as Tokyo Narita–Beijing. The aircraft would allow All Nippon Airways to open new routes to cities not previously served, such as Denver, Moscow, and New Delhi. The 787-3 and 787-8 were to be the initial variants, with the 787-9 entering service in 2010.

Design phase

The 787 was designed to be the first production airliner with the fuselage assembled with one-piece composite barrel sections instead of the multiple aluminium sheets and some 50,000 fasteners used on existing aircraft. Boeing selected two new engine types to power the 787, the General Electric GEnx and Rolls-Royce Trent 1000. Boeing stated the 787 would be approximately 20 percent more fuel-efficient than the 767, with approximately 40 percent of the efficiency gain from the engines, plus gains from aerodynamic improvements, increased use of lighter-weight composite materials, and advanced systems. The 787-8 and −9 were intended to be certified to 330 minute ETOPS capability.

During the design phase, the 787 underwent extensive wind tunnel testing at Boeing's Transonic Wind Tunnel, QinetiQ's five-meter wind tunnel at Farnborough, UK, and NASA Ames Research Centre's wind tunnel, as well as at the French aerodynamics research agency, ONERA. The final styling of the aircraft was more conservative than earlier proposals, with the fin, nose, and cockpit windows changed to a more conventional form. By the end of 2004, customer-announced orders and commitments for the 787 reached 237 aircraft. Boeing initially priced the 787-8 variant at US$120 million, a low figure that surprised the industry. In 2007, the list price was US$146–151.5 million for the 787-3, US$157–167 million for the 787-8 and US$189–200 million for the 787-9.

Manufacturing and suppliers

After stiff competition, Boeing announced on December 16, 2003, that the 787 would be assembled in its factory in Everett, Washington. Instead of building the complete aircraft from the ground up in the traditional manner, final assembly would employ 800 to 1,200 people to join completed subassemblies and to integrate systems. Boeing assigned its global subcontractors to do more assembly themselves and deliver completed subassemblies to Boeing for final assembly. This approach was intended to result in a leaner and simpler assembly line and lower inventory, with pre-installed systems reducing final assembly time by three-quarters to three days.

Subcontracted assemblies included wing manufacture ( Mitsubishi Heavy Industries, Japan, central wing box) horizontal stabilizers ( Alenia Aeronautica, Italy; Korea Aerospace Industries, South Korea); fuselage sections (Global Aeronautica, Italy; Boeing, North Charleston, USA; Kawasaki Heavy Industries, Japan; Spirit AeroSystems, Wichita, USA; Korean Air, South Korea); passenger doors ( Latécoère, France); cargo doors, access doors, and crew escape door ( Saab AB, Sweden); software development ( HCL Enterprise India); floor beams ( TAL Manufacturing Solutions Limited, India); wiring ( Labinal, France); wing-tips, flap support fairings, wheel well bulkhead, and longerons (Korean Air, South Korea); landing gear ( Messier-Dowty, UK/France); and power distribution and management systems, air conditioning packs ( Hamilton Sundstrand, Connecticut, USA). Boeing is considering bringing construction of the 787-9 tail in house; the tail of the 787-8 is currently made by Alenia.

To speed up delivery of the 787's major components, Boeing modified four used 747-400s into 747 Dreamlifters to transport 787 wings, fuselage sections, and other smaller parts. Japanese industrial participation was very important to the project, with Japanese companies co-designing and building of 35% of the aircraft. This was the first time outside firms were given a key role in the design of Boeing airliner wings. The Japanese government also provided support with an estimated US$2 billion in loans. On April 26, 2006, Japanese manufacturer Toray Industries and Boeing announced a production agreement involving US$6 billion worth of carbon fibre, extending a 2004 contract and aimed at easing production concerns. In May 2007 final assembly on the first 787 began at Boeing's Everett, Washington plant.

The 787 project became less lucrative than expected for some subcontractors. Finmeccanica had a total loss of €750 million on the project by 2013.

Production and delivery delays

While Boeing had been working to trim excess weight since assembly of the first airframe began, the company stated in December 2006 that the first six 787s were overweight, with the first aircraft expected to be 5,000 lb (2,300 kg) heavier than specified. In November 2007, Steven F. Udvar-Házy, CEO of International Lease Finance Corporation (ILFC) stated that the 787-9's operating empty weight was around 14,000 lb (6,400 kg) overweight. The seventh and subsequent aircraft would be the first optimized 787-8s and were expected to meet all goals, with Boeing working on weight reductions. As part of this process, Boeing redesigned some parts and made more use of lighter titanium.

Boeing had originally planned for a first flight by the end of August 2007 and premiered the first 787 at a rollout ceremony on July 8, 2007. The aircraft's major systems had not been installed at that time and many parts were attached with temporary non-aerospace fasteners requiring their later replacement with flight fasteners. Although intended to shorten the production process, 787 subcontractors initially had difficulty completing the extra work because they could not procure the needed parts and perform the subassembly on schedule, leaving remaining assembly work for Boeing to complete as "traveled work".

On September 5, Boeing announced a three-month delay, blaming a shortage of fasteners as well as incomplete software. On October 10, 2007, a second three-month delay to the first flight and a six-month delay to first deliveries was announced due to problems with the foreign and domestic supply chain, including an ongoing fastener shortage, the lack of documentation from overseas suppliers, and continuing delays with the flight guidance software. Less than a week later, Mike Bair, the 787 program manager was replaced. On January 16, 2008, Boeing announced a third three-month delay to the first flight of the 787, citing insufficient progress on "traveled work". On March 28, 2008, in an effort to gain more control over the supply chain, Boeing announced that it planned to buy Vought Aircraft Industries' interest in Global Aeronautica; the company later agreed to also buy Vought's North Charleston, S.C. factory.

On April 9, 2008, Boeing officially announced a fourth delay, shifting the maiden flight to the fourth quarter of 2008, and delaying initial deliveries by around 15 months to the third quarter of 2009. The 787-9 variant was postponed to 2012 and the 787-3 variant was to follow with no firm delivery date. On November 4, 2008, the company announced a fifth delay due to incorrect fastener installation and the Boeing machinists strike, stating that the first test flight would not occur in the fourth quarter of 2008. After assessing the 787 program schedule with its suppliers, Boeing confirmed on December 11, 2008, that the first flight would be delayed until the second quarter of 2009.

Airlines, including United Airlines and Air India, have stated their intentions to seek compensation from Boeing for the delays.

Pre-flight ground testing

As Boeing worked with its suppliers on early 787 production, the aircraft design had proceeded through a series of test goals. On August 7, 2007, on-time certification of the Rolls-Royce Trent 1000 engine by European and US regulators was received. On August 23, 2007, a crash test involving a vertical drop of a partial composite fuselage section from about 15 ft (4.6 m) onto a 1 in (25 mm)-thick steel plate occurred in Mesa, Arizona; the results matched what Boeing's engineers had predicted, allowing modeling of various crash scenarios using computational analysis instead of further physical tests. While critics had expressed concerns that a composite fuselage could shatter and burn with toxic fumes during crash landings, Boeing's test data indicated no greater toxicity versus conventional metal airframes. The crash test was the third in a series of demonstrations conducted to match FAA requirements, which included additional certification criteria owing to the 787's introduction of wide-scale composite materials.

The alternative GE GEnx-1B engine achieved certification on March 31, 2008. On June 20, 2008, the 787 team achieved "Power On" of the first aircraft, powering and testing the aircraft's electrical supply and distribution systems. A non-flight 787 test airframe was built for static testing, and on September 27, 2008, over a period of nearly two hours, the fuselage was successfully tested at 14.9 psi (102.7 kPa) differential, which is 150 percent of the maximum pressure expected in commercial service (i.e., when flying at maximum cruising altitude). In December 2008, the Federal Aviation Administration (FAA) passed the maintenance program for the 787.

On May 3, 2009, the first test 787 was moved to the flight line following extensive factory-testing, including landing gear swings, systems integration verification, and a total run-through of the first flight. On May 4, 2009, a press report indicated a 10–15% range reduction, about 6,900 nmi (12,800 km) instead of the originally promised 7,700 to 8,200 nmi (14,800–15,700 km), for early aircraft that were about 8% overweight. Substantial redesign work was expected to correct this, which would complicate increases in production rates; Boeing stated the early 787-8s would have a range of almost 8,000 nmi (14,800 km). As a result, some airlines reportedly delayed deliveries of 787s in order to take later planes that may be closer to the original estimates. Boeing expected to have the weight issues addressed by the 21st production model.

On June 15, 2009, during the Paris Air Show, Boeing said that the 787 would make its first flight within two weeks. However, on June 23, 2009, Boeing announced that the first flight is postponed "due to a need to reinforce an area within the side-of-body section of the aircraft". Boeing provided an updated 787 schedule on August 27, 2009, with the first flight planned to occur by the end of 2009 and deliveries to begin at the end of 2010. The company expected to write off US$2.5 billion because it considered the first three Dreamliners built unsellable and suitable only for flight tests. On October 28, 2009, Boeing announced the selection of Charleston, SC as the site for a second 787 production line, after soliciting bids from multiple states including Washington. On December 12, 2009, the first 787 completed high speed taxi tests, the last major step before flight.

Flight test program

On December 15, 2009, Boeing conducted the Dreamliner's maiden flight with the first 787-8, originating from Snohomish County Airport in Everett, Washington, at 10:27 am PST, and landing at Boeing Field in King County, Washington, at 1:35 pm PST. Originally scheduled for four hours, the test flight was shortened to three hours because of bad weather. Boeing's schedule called for a 9-month flight test campaign (later revised to 8.5 months). The company's previous major aircraft, the 777, took 11 months with nine aircraft, partly to demonstrate 180-min ETOPS, one of its main features.

The 787 flight test program was composed of 6 aircraft, ZA001 through ZA006, four with Rolls-Royce Trent 1000 engines and two with GE GEnx-1B64 engines. The second 787, ZA002 in All Nippon Airways livery, flew to Boeing Field on December 22, 2009, to join the flight test program; the third 787, ZA004 joined the test fleet with its first flight on February 24, 2010, followed by ZA003 on March 14, 2010. On March 24, 2010, testing for flutter and ground effects was completed, clearing the aircraft to fly its entire flight envelope. On March 28, 2010, the 787 completed the ultimate wing load test, which requires that the wings of a fully assembled aircraft be loaded to 150% of design limit load and held for 3 seconds. The wings were flexed approximately 25 ft (7.6 m) upward during the test. Unlike past aircraft however, the wings were not tested to failure. On April 7, Boeing announced that analysis of the data showed the test was a success.

On April 23, 2010, Boeing delivered the newest 787, ZA003, to the McKinley Climatic Laboratory hangar at Eglin Air Force Base, Florida, for extreme weather testing in temperatures ranging from 115 to -45 °F (46 to -43 °C), and prepare it for takeoff at both temperature extremes. Dreamliner ZA005, the fifth 787 and the first with General Electric GEnx engines began ground engine tests in May 2010. ZA005 made its first flight on June 16, 2010 and joined the flight test program. In June 2010, gaps were discovered in the horizontal stabilizers of test aircraft, due to improperly installed shims; all aircraft produced then were to be inspected and repaired. That same month, a 787 experienced an in-flight lightning strike, allowing engineers the opportunity to examine the aircraft's design tolerances. Since composites can have as little as 1/1,000th the electrical conductivity of aluminium, Boeing engineers had added conductive material to ameliorate potential risks and to meet FAA requirements. FAA management was also planning to adjust requirements to help the 787 show compliance. Inspections following the 787's first recorded lightning strike showed no damage to the aircraft.

The 787 made its first appearance at an international air show at the Farnborough Airshow, UK, on July 18, 2010. On August 2, a Trent 1000 engine suffered a blowout at Rolls-Royce's test facility during ground testing. The failure caused Boeing to reevaluate its timeline for installing Trent 1000 engines, and on August 27, 2010 the manufacturer confirmed that the first delivery to launch customer All Nippon Airways would be delayed until early 2011. That same month, Boeing faced compensation claims from airlines owing to ongoing delivery delays. On September 9, 2010, it was reported that a further two 787s might join the test fleet, making a total of eight flight test aircraft. On September 10, 2010, a partial engine surge or runaway occurred in a Trent engine on ZA001 at Roswell. On October 4, 2010, the sixth 787, ZA006 joined the test program with its first flight.

On November 5, 2010, it was reported that some early 787 deliveries may be delayed, in one case some three months, to allow for rework to address problems found during flight testing. On November 9, 2010, Boeing 787, ZA002 made an emergency landing after smoke and flames were detected in the main cabin during a test flight over Texas. A Boeing spokesperson said the airliner landed safely and the crew was evacuated after landing at the Laredo International Airport, Texas. The electrical fire caused some systems to fail before landing. Following this incident, Boeing suspended flight testing on November 10, 2010. Ground testing was performed instead. On November 22, 2010, Boeing announced that the in-flight fire can be primarily attributed to foreign object debris (FOD) that was present in the electrical bay. After electrical system and software changes, the 787 resumed company flight testing on December 23, 2010.

In January 2011, Boeing announced that the first 787 delivery was rescheduled to the third quarter of 2011 due to software and electrical updates following the in-flight fire. On February 24, 2011, Boeing announced that the 787 had completed 80% of the test conditions for Rolls-Royce Trent 1000 engine and 60% of the conditions for the General Electric GEnx-1B engine. On July 4, 2011, All Nippon Airways began a week of airline operations testing using a 787 in Japan. As of August 15, 2011, the 787 test aircraft have flown 4,828 hours in 1,707 flights combined. During testing the 787 has visited 14 countries in Asia, Europe, North America, and South America to test in extreme climates and conditions, and to perform route testing. Boeing completed certification testing for Rolls-Royce powered 787-8s on August 13, 2011. The FAA and European Aviation Safety Agency certified the 787 on August 26, 2011, at a ceremony in Everett, Washington.

Service entry and early operations

Certification of the 787 cleared the way for deliveries. Boeing began preparations to increase 787 production rates from two to ten aircraft per month over the next two years. Production is taking place at assembly lines in Everett and Charleston. The Charleston site's contributions have been clouded by legal difficulties; on April 20, 2011, the National Labor Relations Board alleged that Boeing's second production line in South Carolina violated two sections of the National Labor Relations Act. This labor dispute ended in December 2011 when the National Labor Relations Board dropped its lawsuit after the Machinists union withdrew its complaint as part of a new contract with Boeing. The first 787 assembled at the South Carolina facility was rolled out on April 27, 2012.

The first 787 was officially delivered to All Nippon Airways on September 25, 2011, at Boeing's facilities in Everett, Washington. A ceremony to mark the occasion was also held the next day. On September 27, the Dreamliner flew to Haneda Airport. The airline took delivery of the second 787 on October 13, 2011.

On October 26, 2011, the 787 flew its first commercial flight from Narita to Hong Kong on All Nippon Airways. The airliner was planned to enter service some three years prior. Tickets for the flight were sold in an online auction, with the highest bidder paying $34,000 for a seat. The 787 flew its first commercial long-haul flight on January 21, 2012 from Haneda to Frankfurt on All Nippon Airways.

On December 6, 2011, test aircraft ZA006 (sixth 787 built), powered by General Electric GEnx engines, flew 10,710 nautical miles (19,830 km) non-stop from Boeing Field eastward to Shahjalal International Airport in Dhaka, Bangladesh, setting a new world distance record for aircraft in the 787's weight class, which is between 440,000 pounds (200,000 kg) and 550,000 pounds (250,000 kg). This flight surpassed the previous record of 9,127 nautical miles (16,903 km), set in 2002 by an Airbus A330. The Dreamliner then continued eastbound from Dhaka to return to Boeing Field, setting a world-circling speed record of 42 hours, 27 minutes. In April 2012, an All Nippon Airways 787 made a delivery flight from Boeing in Seattle to Tokyo's Haneda Airport partially using biofuel from cooking oil.

In late 2011, Boeing began a 787 world tour to promote the airliner. It has visited cities in China, Africa, the Middle East, Europe, United States, and others.

According to launch customer ANA data, the 787 surpassed the promised 20% fuel burn reduction, as compared to the Boeing 767. On the Tokyo-Frankfurt route the fuel savings was 21%. As part of this report, ANA surveyed 800 passengers who flew the 787 from Tokyo to Frankfurt: expectations were surpassed for 90% of passengers, and other features that met or exceeded expectations included air quality and cabin pressure (90% of passengers), cabin ambiance (92% of passengers), higher cabin humidity levels (80% of passengers), headroom (40% of passengers) and the larger than usual windows (90% of passengers). 25% said they would go out of their way to again fly on the 787.

Qatar Airways placed its first 787 on display at the Farnborough Airshow in July 2012; the aircraft was to be officially delivered the following month.

On September 15, 2012, the NTSB requested the grounding of certain 787s due to GE engine failures; GE believed the production problem had been fixed by that time.

Design

The 787's design features light-weight construction. The aircraft is 80% composite by volume. Although design changes increased the titanium share, Boeing actually list its materials by weight to 50% composite, 20% aluminium, 15% titanium, 10% steel, and 5% other. Aluminium is used for the wing and tail leading edges; titanium is used mainly on engines and fasteners, with steel used in various areas.

External features include raked wingtips and engine nacelles with noise-reducing serrated edges ( chevrons). The longest-range 787 variant can fly 8,000 to 8,500 nautical miles (15,000 to 15,700 km), enough to cover the Los Angeles to Bangkok or New York City to Hong Kong routes. Cruising airspeed is Mach 0.85 (561 mph, 903 km/h at typical cruise altitudes).

Flight systems

Among 787 flight systems, a key change from traditional airliners is the electrical architecture. The architecture is bleedless and replaces bleed air and hydraulic power sources with electrically powered compressors and pumps, while completely eliminating pneumatics and hydraulics from some subsystems (e.g., engine starters or brakes). Boeing says this system extracts 35% less power from the engines, allowing increased thrust and improved fuel economy. The total available on-board electrical power is 1.45 megawatts, which is five times the power available on conventional pneumatic airliners; the most notable electrically powered systems include: engine start, pressurization, horizontal stabilizer trim, and wheel brakes. Wing ice protection is another new system; it uses electro-thermal heater mats on the wing slats instead of traditional hot bleed air. An active gust alleviation system, similar to the system used on the B-2 bomber, improves ride quality during turbulence.

The 787 has a " fly by wire" control system whose architecture is similar to that of the Boeing 777. The 787 flight deck features LCD multi-function displays, all of which use an industry standard GUI widget toolkit (Cockpit Display System Interfaces to User Systems / ARINC 661). The 787 flight deck includes two head-up displays (HUDs) as a standard feature. Like other Boeing airliners, the 787 uses a yoke instead of a side-stick. Under consideration is future integration of forward looking infrared into the HUD system for thermal sensing. This allows pilots to "see" through the clouds. The Lockheed Martin Orion spacecraft will use a glass cockpit derived from Honeywell International's 787 flight deck systems.

On the 787, Honeywell and Rockwell Collins provided flight control, guidance, and other avionics systems, including standard dual head up guidance systems, Thales supplies the integrated standby flight display and power management, while Meggitt/Securaplane provides the APU starting system, electrical power conversion system, and battery control system with lithium cobalt oxide (LiCo) batteries by GS Yuasa. One of the two batteries weighs 28.5 kg and is rated 29.6 V, 76 Ah, giving 2.2 kWh. Battery charging is controlled by four independent systems to prevent overcharging following early lab testing. The battery systems are the focus of regulatory investigation due to multiple lithium battery fires, which led to grounding of the 787 fleet starting in January 2013.

A version of Ethernet ( Avionics Full-Duplex Switched Ethernet (AFDX) / ARINC 664) will be used to transmit data between the flight deck and aircraft systems. The airplane's control, navigation, and communication systems are networked with the passenger cabin's in-flight internet systems. In January 2008, FAA concerns were reported regarding possible intentional or unintentional passenger access to the 787's computer networks. In response, Boeing stated various airplane protective hardware and software solutions are employed, including air gaps in places to physically separate the networks, and firewalls for software separation. These measures prevent data transfer from the passenger internet system to the maintenance or navigation systems.

Composite materials

Each 787 contains approximately 35 short tons (32,000 kg) of carbon fiber reinforced plastic (CFRP), made with 23 tons of carbon fiber. Carbon fibre composites have a higher strength-to-weight ratio than traditional aircraft materials, and help make the 787 a lighter aircraft. Composites are used on fuselage, wings, tail, doors, and interior. Boeing had built and tested the first commercial aircraft composite section while studying the proposed Sonic Cruiser nearly five years before; the Bell Boeing V-22 Osprey military transport uses 50% composites, and the company's C-17 transport has over 16,000 lb (7,300 kg) of structural composites.

Carbon fibre, unlike metal, does not visibly show cracks and fatigue, prompting concerns about the safety risks of widespread use of the material; the rival Airbus A350 was later announced as using composite panels on a frame, a more traditional approach, which its contractors regarded as less risky. Although later fired, in 2006, Boeing engineer Vince Weldon complained to management, then later in public: the composite fuselage was unsafe compared to traditional aluminium designs, and in a crash, was more likely to "shatter too easily and burn with toxic fumes".

In addition, a potential issue is the porous nature of composite materials: collected moisture expanding with altitude can cause delamination. Boeing responded by noting: composites have been used on wings and other passenger aircraft parts for many years without incident, and special defect detection procedures will be instituted for the 787 to detect any potential hidden damage.

In 2006, Boeing launched the 787 GoldCare program. This is an optional, comprehensive life-cycle management service, whereby aircraft in the program are routinely monitored and repaired, as needed. Although the first program of its kind from Boeing, post-sale protection programs are not new; such programs are usually offered by third party service centers. Boeing is also designing and testing composite hardware so inspections are mainly visual. This will reduce the need for ultrasonic and other non-visual inspection methods, saving time and money.

Engines

The 787 features two engines; these engines use all-electrical bleedless systems, eliminating the superheated air conduits normally used for aircraft power, de-icing, and other functions. As part of its "Quiet Technology Demonstrator 2" project, Boeing adopted several engine noise-reducing technologies for the 787. Among these are a redesigned air inlet containing sound-absorbing materials and redesigned exhaust duct covers whose rims are tipped in a toothed pattern called chevrons to allow for quieter mixing of exhaust and outside air. Boeing expects these developments to make the 787 significantly quieter both inside and out. The noise-reducing measures ensure that sounds above 85 decibels do not leave airport boundaries.

The two different engine models compatible with the 787 use a standard electrical interface to allow an aircraft to be fitted with either Rolls-Royce Trent 1000 or General Electric GEnx engines. This aims to save time and cost when changing engine types; while previous aircraft can have engines changed to those of a different manufacturer, the high cost and time required makes it rare. In 2006, Boeing addressed reports of an extended change period by stating that the 787 engine swap was intended to take 24 hours; engine interchangeability, it is reported, makes the 787 a more flexible asset to airlines, allowing them to change easily from one manufacturer's engine to the other if required.

Interior

The 787-8 is designed to typically seat 234 passengers in a three-class setup, 240 in two-class domestic configuration, and 296 passengers in a high-density economy arrangement. Seat rows can be arranged in four to seven abreast in first or business (e.g., 1–2–1, 2–2–2, 2-3-2). Eight or nine abreast are options in economy (e.g., 3–2–3, 2–4–2, 3–3–3). Typical seat room ranges from 46 to 61 in (120 to 150 cm) pitch in first, 36 to 39 in (91 to 99 cm) in business, and 32 to 34 in (81 to 86 cm) in economy.

Cabin interior width is approximately 18 feet (550 cm) at armrest level, which is 1 inch (2.5 cm) more than originally planned. The Dreamliner's cabin width is 15 inches (38 cm) more than that of the Airbus A330 and A340, 5 inches (13 cm) less than the A350, and 16 in (41 cm) less than the 777. Airlines use economy seat widths that range from 16.33 in (41.5 cm) to 20.66 in (52.5 cm). 787 economy seats are approximately 17.2 in (43.7 cm) for nine-abreast seating and 19 inches (48 cm) wide for eight-abreast seating arrangements. Most airlines are selecting the nine-abreast (3–3–3) configuration. Boeing engineers designed the 787 interior to better accommodate persons with mobility, sensory, and cognitive disabilities. For example, a 56 in (140 cm) by 57 in (140 cm) convertible lavatory includes a movable centre wall that allows two separate lavatories to become one large, wheelchair-accessible facility.

The 787's cabin windows are larger in area than any other civil air transport in-service or in development, with dimensions of 10.7 by 18.4 in (27 by 47 cm), and a higher eye level so passengers can maintain a view of the horizon. The composite fuselage permits larger windows without the need for structural reinforcement. Instead of window shades, the windows use electrochromism-based smart glass (supplied by PPG Industries) allowing flight attendants and passengers to adjust five levels of sunlight and visibility to their liking, reducing cabin glare while maintaining a view to the outside world, but the most opaque setting still has some transparency. However the lavatory still has a traditional sunshade. The 787's cabin features light-emitting diodes (LEDs) as standard equipment, allowing the aircraft to be entirely 'bulbless'. LED lights have previously been an option on Airbus aircraft and the Boeing 777. The system is based on three color plus white LEDs instead of fluorescent tubes, allowing any colour and brightness.

The internal cabin pressure of the 787 is increased to the equivalent of 6,000 feet (1,800 m) altitude instead of the 8,000 feet (2,400 m) on older conventional aircraft. According to Boeing, in a joint study with Oklahoma State University, this will significantly improve passenger comfort. Cabin air pressurization is provided by electrically driven compressors, rather than traditional engine-bleed air, thereby eliminating the need to cool heated air before it enters the cabin. The cabin's humidity is programmable based on the number of passengers carried, and allows 15% humidity settings instead of the 4% found in previous aircraft. The composite fuselage avoids the metal fatigue associated with higher cabin pressure, and eliminates the risk of corrosion from higher humidity levels. The cabin air-conditioning system improves air quality by removing ozone from outside air, and besides standard HEPA filters which remove airborne particles, uses a gaseous filtration system to remove odours, irritants, and gaseous contaminants as well as particulates like viruses, bacteria and allergens.

Variants

Boeing has offered three variants of the 787 from the program launch in 2004. The 787-8 is the first variant produced and is to be followed by the 787-9.

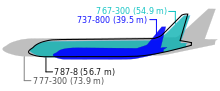

787-8

The 787-8 is the base model of the 787 family, with a length of 186 feet (57 m) and a wingspan of 197 feet (60 m) and a range of 7,650 to 8,200 nautical miles (14,170 to 15,200 km), depending on seating configuration. It is the only 787 variant, and the third Boeing widebody (after the 747SP and the 777-200LR) with a wingspan wider than the length of the fuselage. The 787-8 seats 210 passengers in a three-class configuration. The variant was the first of the 787 line to enter service, entering service in 2011. Boeing is targeting the 787-8 to replace the 767-200ER and 767-300ER, as well as expand into new non-stop markets where larger planes would not be economically viable. Two-thirds of 787 orders are for the 787-8.

787-9

The 787-9 will be the first variant of the 787 with a "stretched" or lengthened fuselage, seating 250–290 in three classes with a range of 8,000 to 8,500 nautical miles (14,800 to 15,750 km). This variant differs from the 787-8 in several ways, including structural strengthening, a lengthened fuselage, a higher fuel capacity, a higher maximum take-off weight (MTOW), but with the same wingspan as the 787-8. The targeted entry into service (EIS) date, was originally planned for 2010, but by October 2011 deliveries were scheduled to begin in early 2014. Boeing is targeting the 787-9 to compete with both passenger variants of the Airbus A330 and to replace their own 767-400ER. Like the 787-8, it will also open up new non-stop routes. The firm configuration was finalized on July 1, 2010.

When first launched, the 787-9 had the same fuel capacity as the other two variants. The design differences meant higher weight and resulted in a slightly shorter range than the 787-8. After further consultation with airlines, design changes were incorporated to add a forward tank to increase its fuel capacity, so it has a longer range and a higher MTOW than the other two variants. Air New Zealand is the launch customer for the 787-9.

Other variants

787-3

The-3 was targeted for high-density flights; it was designed as a 290-seat (two-class) short-range version with a fully loaded range of 2,500 to 3,050 nautical miles (4,650 to 5,650 km). Using the same basic fuselage as the 787-8, the wing was derived from the 787-8, with blended winglets replacing raked wingtips. The change decreased the wingspan by roughly 25 feet (7.6 m), allowing the 787-3 to fit more domestic gates, and particular within Japan. This model would have been limited in range by a reduced MTOW of 364,000 lb (165,100 kg).

The −3 variant was designed to operate on Boeing 757-300/ 767-200-sized regional routes from airports with restricted gate spacing. Boeing projected the future of aviation as between very large, but close cities, of five million or more people; city populations may stabilize around the capacity level of the 787-3.

Forty-three 787-3s were ordered by the two Japanese airlines; however, production problems on the base 787-8 model led Boeing, in April 2008, to postpone the introduction of the 787-3 until after the 787-9's introduction, but without a firm delivery date. By January 2010, all 787-3 orders had been converted to the 787-8. Following the lack of interest by potential customers, caused by its being designed specifically for the Japanese market at the time, it seemed the 787-3 variant would be shelved entirely. On December 13, 2010, after its orders were canceled, Boeing canceled the 787-3: it was no longer financially viable.

787-10

Boeing has stated that it is likely to develop another version, the longer 787-10, with seating capacity between 290 and 310. This proposed model is intended to compete with the planned Airbus A350-900. The 787-10 would supersede the 777-200ER in Boeing's current catalog and could also compete against the Airbus A330-300 and A340-300. Boeing was having discussions with potential customers about the 787-10 in 2006 and 2007. In March 2006 Mike Bair, the head of the 787 program at the time, stated that "It's not a matter of if, but when we are going to do it ... The 787-10 will be a stretched version of the 787-9 and sacrifice some range to add extra seat and cargo capacity." Boeing has not yet officially launched the −10, but it remains under consideration as of 2012.

Further proposals

Although with no set date, Boeing expects to build, possibly in 10 to 15 years, a 787 freighter version. Boeing is reportedly also considering a 787 variant as a candidate to replace the 747-based VC-25 as Air Force One.

Operators

- All Nippon Airways first service October 26, 2011

- Japan Airlines first service on May 1, 2012

- Ethiopian Airlines first service on August 16, 2012

- Air India first service on September 19, 2012

- LAN Airlines first service on October 1, 2012

- United Airlines first service on November 4, 2012

- Qatar Airways first service on November 20, 2012.

- LOT Polish Airlines first service on December 14, 2012.

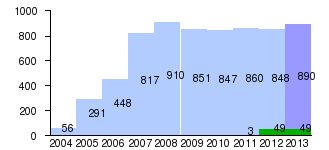

Orders and deliveries

In September 2011, the 787 was first officially delivered to launch customer All Nippon Airways. As of August 2012, the top three customers for the 787 are: ILFC (International Lease Finance Corporation), with orders totaling 74 Boeing 787s (33 -8s and 41 -9s); All Nippon Airways with 66 orders (36 -8s and 30 -9s); and United Airlines, with 50 orders (36 -8s and 14 -9s). Qantas had 50 orders (15 -8s and 35 -9s) but converted the 787-9 portion of the orders to options, because of delays, and in an effort to reduce near-term costs; this after statutory losses of over US$250 million after taxes, during the 2011–2012 fiscal year.

|

| Data through February 5, 2013 |

| 787-8 | 787-9 | Total orders |

| 543 | 347 | 890 |

| 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | Total | |

| Net orders | 56 | 235 | 157 | 369 | 93 | -59 | -4 | 13 | -12 | 42 | 890 |

| Deliveries | – | – | – | – | – | – | – | 3 | 46 | - | 49 |

- Data through February 5, 2013

Incidents and accidents

The Boeing 787 has been involved in one aviation occurrence and no hull-loss accidents as of February 2013.

On January 16, 2013, All Nippon Airways Flight NH-692, en route from Ube to Tokyo Haneda, had received indications of battery problems, followed by a burning smell while climbing from Ube, about 35 nautical miles west of Takamatsu, Japan. The pilots decided to divert to Takamatsu, where the plane landed, vacated the runway, and was evacuated via slides. One passenger received a serious injury, and two other passengers received minor injuries during the evacuation. Inspection of the battery compartment revealed that they had suffered a battery fire. This, along with a very similar incident of a parked Japan Airlines 787 at Boston's Logan International Airport that also had a battery fire within the same week, led the Federal Aviation Administration to ground all Boeing 787s in service at the time.

Operational problems

| Wikinews has related news: FAA orders review of Boeing 787 Dreamliners following week of incidents |

The 787 has suffered from a number of problems during its launch, though only two of the problems are related to difficulties that are above and beyond regular wear and tear. In December 2012, Boeing CEO James McNerney told media outlets that the problems were no greater than those experienced by the company with the introduction of other new models, such as the Boeing 777. A JAL 787 experienced a fuel leak on January 8, and its flight from Boston was canceled.

On January 9, United Airlines reported a problem in one of its six 787s with the wiring in the same area as the battery fire on the JAL 787. After these incidents, the U.S. National Transportation Safety Board subsequently opened a safety probe. Later, on January 11, 2013, another aircraft was found to have a fuel leak, That same day the FAA announced a comprehensive review of the 787's critical systems, including the design, manufacture and assembly; U.S. Department of Transportation secretary Ray LaHood stated the administration was "looking for the root causes" behind the recent issues. The head of the FAA, Michael Huerta, said that so far nothing found "suggests [the 787] is not safe".

On January 13, 2013, a Japan Airlines 787 at Narita International Airport outside of Tokyo, was found to also have a fuel leak during an inspection, the third time a fuel leak had been reported within a week. The aircraft reportedly was the same one that had a fuel leak in Boston on January 8. This leak, however, was caused by a different valve; the causes of the leaks are unknown. Japan's transport ministry have also launched an investigation.

US-based aviation regulators oversight into the 2007 safety approval and FAA certification of the 787 has now come under scrutiny, as a key US Senate committee prepare "in coming weeks" for a hearing into the procedures of aviation safety certification.

Groundings

On January 16, 2013, both major Japanese airlines ANA and JAL announced that they were voluntarily grounding or suspending flights for their fleets of 787s after multiple incidents involving different 787s, including emergency landings. These two carriers operate 24 of the 50 Dreamliners delivered to date. The grounding could cost ANA over $1.1 million a day.

On January 16, 2013, the FAA issued an emergency airworthiness directive ordering all U.S.-based airlines to ground their Boeing 787s until yet-to-be-determined modifications are made to the electrical system to reduce the risk of the battery overheating or catching fire. This is the first time that the FAA has grounded an airliner type since 1979. Industry experts disagree on consequences of the grounding: Airbus is confident that Boeing will resolve the issue and that no airlines will switch plane type, while other experts see the problem as "costly" and "could take upwards of a year".

The FAA also announced plans to conduct an extensive review of the 787's critical systems. The focus of the review will be on the safety of the lithium-ion batteries made of lithium cobalt oxide (LiCo). The 787 battery contract was signed in 2005, when LiCo batteries were the only type of lithium aerospace battery available, but since then newer and safer types (such as LiFePO), which provide less reaction energy during thermal runaway, have become available. FAA approved a 787 battery in 2007 with nine "special conditions". A battery approved by FAA (through Mobile Power Solutions) was made by Rose Electronics using Kokam cells; the batteries installed in the 787 are made by Yuasa.

On January 20, the NTSB declared that overvoltage was not the cause of the Boston incident, as voltage did not exceed the battery limit of 32 V, and the charging unit passed tests. The battery had signs of short circuiting and thermal runaway. Despite this, the NTSB announced on January 24 that it had not yet pinpointed the cause of the Boston fire; the FAA will not allow U.S.-based Dreamliners to fly again until the problem is found and corrected. In a press briefing that day, NTSB Chairwoman Deborah Hersman said that the NTSB had found evidence of failure of multiple safety systems designed to prevent these battery problems, and stated that fire must never happen on an airplane.

The Japan Transport Safety Board (JTSB) has said on January 23 that the battery in ANA jets in Japan reached a maximum voltage of 31 V (lower than the 32 V limit like the Boston JAL 787), but had a sudden unexplained voltage drop to near zero. All cells had signs of thermal damage before thermal runaway. ANA and JAL had replaced several 787 batteries before the mishaps. As of January 29, 2013, JTSB approved the Yuasa factory quality control while the NTSB continues to look for defects in the Boston battery. The two major battery thermal runaway events in 100,000 flight hours substantially exceeded the 10 million flight hours predicted by Boeing.

The only U.S.-based airline that operates the Dreamliner is United Airlines, which has six. Chile's Directorate General of Civil Aviation (DGAC) grounded LAN Airlines' three 787s. The Indian Directorate General of Civil Aviation (DGCA) directed Air India to ground its six Dreamliners. The Japanese Transport Ministry made the ANA and JAL groundings official and indefinite following the FAA announcement. The European Aviation Safety Agency has also followed the FAA's advice and grounded the only two European 787s operated by LOT Polish Airlines. Qatar Airways has announced that they are grounding their five Dreamliners. Ethiopian Air was the final operator to announce temporary groundings of its four Dreamliners.

As of January 17, 2013, all 50 of the aircraft delivered to date have been grounded. On January 18, Boeing announced that it was halting 787 deliveries until the battery problem is resolved. On February 7, 2013, the FAA gave approval for Boeing to conduct 787 test flights to gather additional data.

On February 28, 2013, ANA and JAL canceled their 787 flights through the end of May 2013.

On March 7, 2013, the National Transportation Safety Board released an interim factual report about the 787 battery fire at Boston's Logan Airport on January 7, 2013. The investigation stated that "heavy smoke and fire coming from the front of the APU battery case". Firefighters "tried fire extinguishing, but smoke and flame (flame size about 3 inches) did not stop".

Specifications

| Model | 787-8 | 787-9 |

|---|---|---|

| Cockpit crew | Two | |

| Seating, typical | 242 (3-class) 264 (2-class) |

250–290 280 (3-class) |

| Length | 186 ft (56.7 m) | 206 ft (62.8 m) |

| Wingspan | 197 ft 0 in (60.0 m) | |

| Wing area | 3,501 sq ft (325 m2) | |

| Wing sweepback | 32.2 degrees | |

| Height | 55 ft 6 in (16.9 m) | |

| Fuselage dimensions | Width: 18 ft 11 in (5.77 m) / Height: 19 ft 7 in (5.97 m) | |

| Maximum cabin width | 18 ft (5.49 m) | |

| Cargo capacity | 4,822 cu ft (137 m3) 28× LD3 or 9x (88x125) pallets or 8x (96x125) pallets + 2x LD3 |

6,086 cu ft (172 m3) 36× LD3 or 11x (88x125) pallets or 11x (96x125) pallets |

| Maximum takeoff weight | 502,500 lb (228,000 kg) | 553,000 lb (251,000 kg) |

| Maximum landing weight | 380,000 lb (172,000 kg) | 425,000 lb (193,000 kg) |

| Maximum zero-fuel weight | 355,000 lb (161,000 kg) | 400,000 lb (181,000 kg) |

| Operating empty weight | 242,000 lb (110,000 kg) | 254,000 lb (115,000 kg) |

| Cruising speed | Mach 0.85 (567 mph, 490 knots, 913 km/h at 35,000 ft/10,700 m) | |

| Maximum speed | Mach 0.89 (593 mph, 515 knots, 954 km/h at 35,000 ft/10,700 m) | |

| Range, fully loaded | 7,650–8,200 nmi (14,200–15,200 km; 8,800–9,440 mi) | 8,000–8,500 nmi (14,800–15,700 km; 9,210–9,780 mi) |

| Takeoff distance at MTOW (sea level, ISA) |

10,300 ft (3,100 m) High Thrust Rating: 8,500 ft (2,600 m) |

|

| Maximum fuel capacity | 33,528 US gal (126,920 L) | 36,641 US gal (138,700 L) |

| Service ceiling | 43,000 ft (13,100 m) | |

| Engines (×2) | General Electric GEnx or Rolls-Royce Trent 1000 | |

| Thrust (×2) | 64,000 lbf (280 kN) | 71,000 lbf (320 kN) |

Sources: 787 brochure, 787-8 Airport report, 787 fact sheets